One of the first beers I made successfully was Weizen.

I followed a recipe from a dutch beer making book that I really like. Unfortunately it is not available in other languages. There are only a few recipes in it but they are very detailed so you can check if your result is what it should be.

Many recipes will not tell the Starting SG or the alcohol percentage so you often have no idea if you extracted enough sugar from the malts.

Here is the recipe for 10 liters

Starting SG: 1.056 or 13,9 Plato

End SG: 1.011 or 2,8 Plato

Alcohol: 5,9 %

Fermentables:

EBC Amount (kg)

Pils 3 0,189

Wheat malt 3 1,215

Vienna malt 6 0,691

Mashing

Temperature 44 50 60 70 78

Time 10 15 25 25 5

Hops Alpha acids Time Amount

Hallertau tradition 5% 75min 9,2 gm

Boiling 90 min.

Yeast

Safbrew WB-06

Fermenting temperature

Primary fermentation 17

Secondary fermentation 20

Bottling sugar

9 gr/l

This is my grinder. It is expensive but it works great. I use the bucket for filtering to catch the malt. I really like this part of the job, especially for the lovely scent of the ground malt.

This is my cooker. At first I was not so happy with it because it did not work as I expected. Now I am happy with it but I am not sure if I would buy it again. I think that there are cheaper alternatives that work just as good.

Preheat the water to the starting temperature (a bit higher) before adding the malts.

You can see the contribution that wheat malt has in the color of the wort.

This is the bucket I use for filtering. There are other ways but I am very happy with this bucket. It is nothing special but it works really well.

Here is the set up for the cooling. When I first started making beer I was in a hurry to cool the beer immediately after boiling. I made it a bit stressful. Now I am more relaxed and let the wort cool down a little bit so the leftover hops and other solids can settle on the bottom of the cooker.

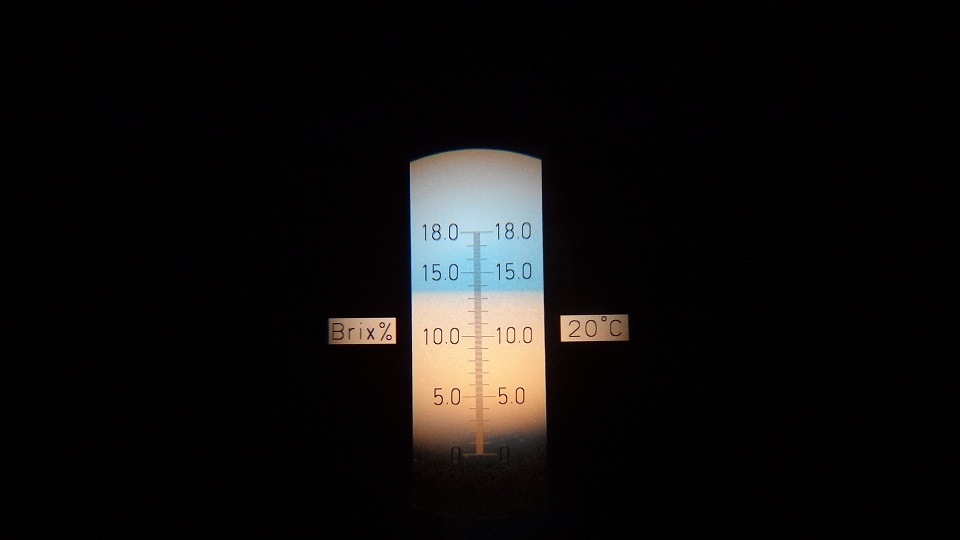

After the wort is cooled I make a measurement with the refractometer. I found that the S.G. was not enough so I had to add some sugar until it was about right.

After a few days I rack the fermenting wort into a glass demijohn. It introduces a bit oxygen again which is good for the yeast. In a later stage you want to avoid oxygen so I choose for a demijohn with little room for air above the beer. This step should not be really necessary because the beer is covered with a layer CO2 but I like to see what is happening and I think that the demijohn is a beautiful tool.

I have no control over the temperature at this time so it is room temperature. I am sure that beer will be the result.

Cheers

Hans