When I started making cheese I did not want to spend any money before I knew whether I would like it as a hobby. So I made moulds out of a PVC pipe and I also made the followers and decided that I would press the cheese directly with some weights.

After some experimenting and adjusting I made it work. Now that I have made several cheeses I decided that it is fun and tasty so I will continue to make cheeses. Therefore I decided to invest in a cheese press.

There are some serious advantages to a press. First of all it is stable. I once left my self made construction to press overnight and found it collapsed the next morning.

Fortunately the cheese was ok.

Fortunately the cheese was ok.

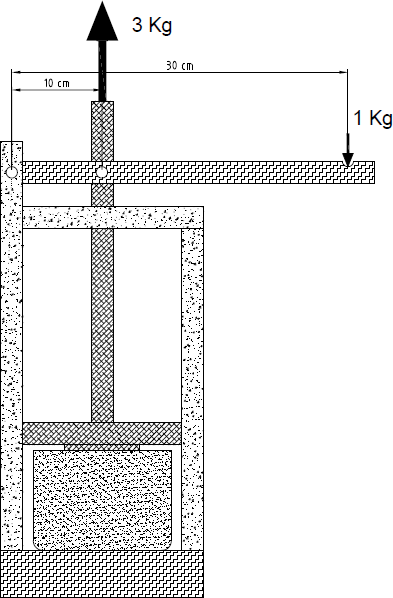

Second; due to the leverage you need less weight to press. The press that I bought will press the cheese with 3 kg when only 1 kg is applied to the arm. It is simple to calculate but the picture will make it more clear. If you have a different press you can use the same logic to calculate your weight.

The formula in this case is: 1 kg x 30 cm = 3 kg x 10 cm

I made some pictures of the built. It is pretty straightforward. You only need a screwdriver. The holes are pre drilled. There is one thing that you can do wrong. Before mounting the top plate you have to put the pressing rod in the slots because you cannot fit it in afterwards.

The first try gave me a surprise. I like the quality of the wood and the press in general. However the construction has a flaw. When you place the weight it will fall forward. This was a bit disappointing however the problem can be fixed easily by placing a weight on the other side. This works very well and the construction is much easier to handle than my own built. You don’t have to handle a lot of weight to get the right pressing weight.

Of course it is not too difficult to make a press yourself. This is for hobby cheese makers and you cannot fit very big cheeses inside. The maximum diameter of the mould is 16 cm. Which is enough for me.

Hans