A few years ago I bought myself a present: A wine refrigerator!

I was very happy with it but also a bit ashamed of this snobbish piece of equipment which nobody really needs. You don’t get the combination of these feelings very often.

Shortly after buying it I realized that it is a great place to let cheeses ripen. Only at that moment I started making cheese. The refrigerator was suddenly a tool that I could not miss.

A few months ago I noticed that there was something wrong. It became more noisy and the motor would not stop running. The motor was also very hot. It even had big problems to keep the temperature at 18C.

I googled to see if I could find out what the problem could be. The motor was running, the thermostat was working… Many more options are not available and based on my research I concluded that the coolant had leaked out of the system.

On some Dutch “do it yourself” sites I saw the advice “Throw it away and buy a new one!” because the repair would be too expensive.

I was pretty angry about it because it is only 4 years old! It is an AEG so I expect German quality. Unfortunately the German quality was “made in China”.

The first thing I tried was kicking it very hard but that did not help. I googled some more and I found some movies that showed that it is not so difficult to refill a refrigerator. Nobody mentioned anything about fixing the leak but after some more googling I read somewhere that the leak could be extremely small.

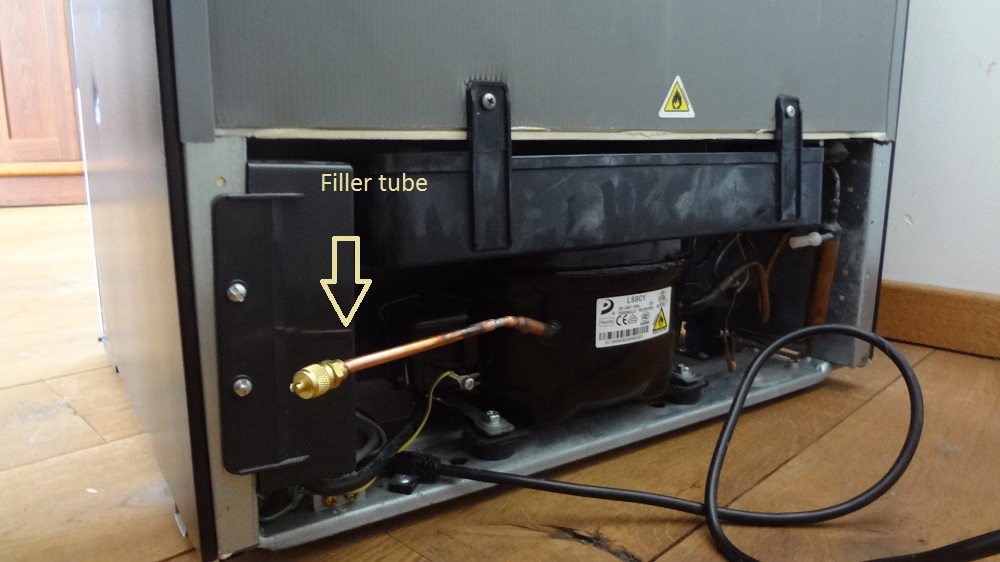

I decided to have a look for the equipment and try to fix it. I found a site with a copper filler tube which you have to solder to the refrigerator, a gas bottle and a tap for the bottle. That looked promising so I ordered them. I decided that I could find a tube needed to connect the filler tube to the tap in a hardware shop.

That was a mistake. The thread of the copper filler tube mentioned ¼” but it definitely was not the G¼” that is available. It turned out to be SAE which is not used regularly. But luckily I found a website that sells a tube with this thread. By now I spent 100 euro without any guarantee.

Now was the moment of truth. I cut the filler line and soldered the filler tube in it. This went surprisingly easy considering I have not soldered before.

On the refrigerator is mentioned that I should get 25 gram of the gas R600a in it.

I connected the can, the tap, and the tube to the filler and opened the tap. I could hear the gas flowing but it was not much. I weighed the can and it was only about 12 gram lighter.

Then I remembered that the motor should be running!

I connected it again and switched on the refrigerator. This time I could hear that the motor sucked in more gas.

I disconnected everything and closed the filler with its cap.

This time approximately 30 gram went in. I did not have any patience so I let the refrigerator running. It worked great! The outside became warm and the temperature in the refrigerator dropped really quick.

It is working for 2 months now and I am sure that it is working better than when it was new. It is cooling faster and it is not as noisy. And the funny thing is that the filler is still there! I have enough gas for 10 more refills so if it happens again I can simply fill it again.

You can believe that I am really happy with the result. I can make cheese again.

Hans

Read the update